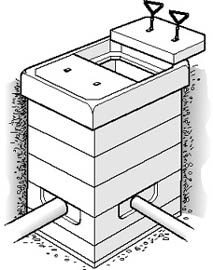

Sectional Inspection Chamber

Internal dimensions: 915mm x 685mm with 300mm silt capacity

Modules: 150mm (63kg), 180mm (73kg), 225mm (93kg), 300mm (125kg)

suitable for pipes up to 380mm OD

Approximate weight with no lid: 320kg

Machine-made reinforced concrete sections to B.S.5911 part 2, that can be easily and quickly assembled to form chambers of varying depths. The basic chamber consists of a base frame with insert; a bottom section 180mm deep with a rebate on the top edge only; and a 300mm deep section with knock-out webs which will accommodate pipe sizes up to 180mm o.d. For larger pipe sizes either a 180mm or 300mm deep section with knock-out webs is added. Plain extension sections are available where it is required to have access to the chamber at ground level. There is a range of lids and cover slabs available.

Sub-surface lid

Approximate weight with no lid: 120kg.

65mm reinforced concrete frame with circular removable lid. Designed to have at least 560mm of cover under normal agricultural situations. Suitable for pedestrian use at ground level.

Removable steel lid

Approximate weight: 165kg.

Steel frame is cast into a strongly reinforced concrete surround 100mm thick into which a standard galvanized 17 tonne GVW pressed steel manhole lid is fitted.

Heavy duty concrete lid

Approximate weight: 270kg.

The 180mm deep concrete lid frame is designed to provide a full size clear opening. The two 125mm thick lids locate neatly in the frame and can only be removed with the proper lifting keys. Designed for use at ground level where normal farm traffic conditions exit. Where constant traffic is expected, the frame should be bedded on mortar and surround with concrete.

Playing field top

Approximate weight: 160kg.

Where ground level access to an inspection chamber is required on a playing field, it is desirable to minimize the amount of concrete exposed at the playing surface. The J.K.H. playing field top is a 100mm think reinforced concrete cover slab with a 460mm x 600mm opening cast through. To achieve the required finished level, bricks are mortared around the opening and the lid is then fitted on top.

Surface water top

Approximate weight: 200kg.

The 100mm thick lid frame has a 405mm x 305mm opening cast through into which a removable galvanized steel trash box and grating are fitted. This enables surface water to be safely removed into a piped drain.

Note

With a newly installed under-drainage system, the maximum amount of silting-up is known to occur during the first 9 months or so. Therefore, ideally final backfilling should be delayed so that the chamber can be inspected during this period.

INSTALLATION

Excavate pit approximately 1100mm x 800mm to a depth of 370mm below pipe level to allow for thickness of base and the silt capacity of the first extensions. Check bottom of pit is level and sufficient size. Slide the base frame down so that it rests on one edge. Work it over to the side of the pit, and as you lay it down (rebates facing up), step into the centre opening. Line it up with the drains and check that it is level. Take the 180mm deep I.C. section and place on the base frame (rebated edge facing up). Using abrasive disc angle grinder cut out the relevant knockout webs in the 300mm deep I.C. section before lifting it into the pit and locating it on the first section. Carefully backfill around the chamber and consolidate up to underside of pipe level. Connect the drain runs, preferably using rigid, non- porous pipes of the correct length so that they come flush with the inside of the chamber. Make good around the pipes with cement mortar. Clear the opening in the base frame before fitting the base insert. Fit the sub-surface frame and lid or extra extensions as required. Continue with the backfilling, carefully consolidating as you proceed.